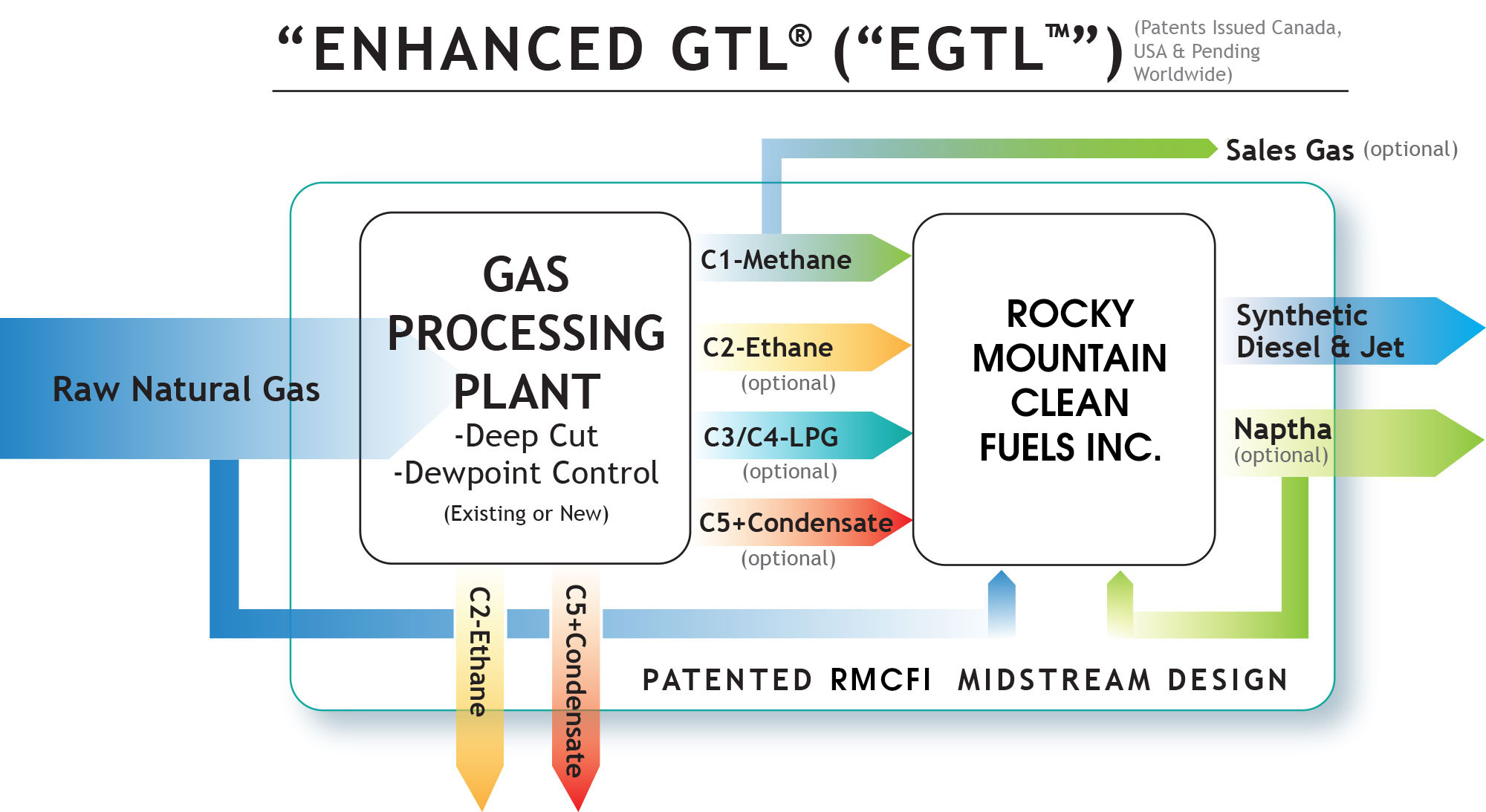

Rocky Mountain Clean Fuels Inc. designs, constructs, and operates, small scale modular Fischer-Tropsch gas to liquids (GTL) plants to convert natural gas and natural gas liquids into synthetic fuel.

Forging the road ahead, our patented technology adds value to natural gas resources while optimizing fuel production and improving environmental performance.

In 2017 Rocky Mountain GTL Inc. purchased the patented Enhanced GTL® technology from Expander Energy Inc. These patents are being filed worldwide. (Canadian Patent Numbers 2751615, 2776369 and 2843088).

Rocky Mountain Clean Fuels Inc. recycles low value by-products (such as naphtha, propane and butane) and converts them into high-quality fuel products, adding value to the natural resource and increasing marketability.

We convert natural gas, natural gas liquids (NGLs) and liquid petroleum gas (LPGs) into synthetic fuel through the combination of Rocky Mountain Clean Fuels Inc.’s feedstock flexible EGTL™ technology along with Greyrock Energy “Direct to Fuel” production catalyst. This unique process targets liquid paraffin and eliminates complex refining (no oxygen plant, no hydro-cracker) that plague other GTL fuel producers. Our plants are designed to be water neutral and generate surplus power.

Our EGTL™ process utilizes only proven and licensable technologies that have been accepted by industry for decades. Our unique technology process patent is on the configuration of these proven technologies. Our small scale EGTL™ plants can be greenfield or integrated into existing gas processing facilities. Production can range from 25 million litres per year to 300 million litres per year depending on the plant size.

Rocky Mountain Clean Fuels Inc.’s EGTL™ plants provide the producer complete flexibility for the processing and sale of natural gas maximizing “bottom-line” performance.

For the same or less cost than standard diesel production, we open doors to local or regional energy markets for natural gas producers. Our plants can stand alone for stranded gas reserves or built parallel to existing gas facilities.